MEGS Biaxial Geogrid: High-Performance Pavement Reinforcement

Strength Engineered by Strata. Delivered by MEGS.Empowering infrastructure with globally trusted geogrid technology MEGS brings you Strata’s advanced solutions for durable, efficient, and sustainable ground reinforcement

MEGS proudly partners with Strata Geosystems to deliver the region’s leading geosynthetic solution—StrataGrid™ Biaxial Geogrid. Designed for flexible pavement and subgrade reinforcement, StrataGrid™ combines high-strength performance with sustainable engineering.

With tensile strengths from 20kN/m to 150kN/m and a wide 5-meter format, this biaxial geogrid enhances load distribution, reduces pavement crust thickness, and extends infrastructure lifespan.

Through our technical support, consultation, and supply services, MEGS ensures Strata’s cutting-edge geogrid systems are expertly applied across various infrastructure projects. Compliant with MoRTH and IRC standards, StrataGrid™ Biaxial Geogrid is trusted across the region for projects requiring lasting performance and environmental responsibility.

Geocell is especially useful in projects such as roads, parking lots, embankments, and drainage channels. It increases the strength of weak soils by spreading loads more evenly, which extends the lifespan of structures and reduces maintenance needs. On slopes, it helps control erosion and water runoff, keeping the soil in place and maintaining the shape of the land.

Another key advantage of Geocell is its ability to work with locally available materials like sand, gravel, or soil, making it both cost-efficient and environmentally friendly. MEGS integrates Geocell into its ground improvement projects to deliver smart, sustainable, and durable infrastructure solutions.

StrataWeb® is a ground breaking solution for soil reinforcement and erosion control, specially engineered to tackle some of the most daunting engineering challenges. At the heart of this solution is its unique honeycomb-like structure, designed to efficiently manage soil and environmental conditions. Made from interconnected polymer strips, this three-dimensional system is both flexible and robust, providing superior support by securing soil and other materials in place.

What makes our Biaxial Geogrid unique?

What makes our Biaxial Geogrid unique?

-

Superior Pavement Strength

Boosts the modulus of base layers, increasing road durability and reducing cracking and rutting.

-

Efficient Installation

Wide-format rolls reduce overlaps and speed up deployment, minimizing material waste.

-

Economical & Cost-Effective

Reduces required pavement thickness and lowers long-term repair costs.

-

Sustainable Performance

Decreases environmental impact by minimizing resource consumption and construction time.

-

Certified and Compliant

Meets MoRTH and IRC standards and is tested for quality and durability

What impact does our Biaxial Geogrid create?

What impact does our Biaxial Geogrid create?

Environmental

Time-efficient

Economical

Applications of StrataWeb® Geocell

Applications of StrataWeb® Geocell

Embankment over soft soils using Biaxial Geogrid

Embankments Over Soft Soils provides reliable basal reinforcement over weak subgrades, increasing load distribution, preventing settlement, and improving the stability of highway embankments.

Flexible pavement or asphalt reinforcement with Biaxial Geogrid

Flexible Pavement Reinforcement Strengthens base layers in asphalt pavements, reducing rutting, cracking, and maintenance frequency while improving road lifespan.

Below structural foundations using Biaxial Geogrid

for enhancing bearing capacity and minimizing differential settlement under deep foundations such as bridges, retaining walls, and industrial structures.

Load transfer platform and void spanning using Biaxial Geogrid

Load Transfer Platforms and Void Spanning ensures even load transfer over voids or unstable ground, safeguarding infrastructure with strong, consistent support.

Manufacturing Process of OUR Biaxial Geogrid

Manufacturing Process of OUR Biaxial Geogrid

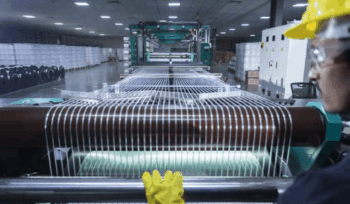

Beaming

Polyester yarns are pulled from creels and wound onto beams using automated systems, ensuring consistent tension and quality.

Knitting

Yarns are precisely knitted into stable apertures using high-speed knitting machines, forming a strong geogrid matrix.

Coating

The knitted grid is coated with a proprietary SBR-based compound to enhance resistance against damage during installation and ensure dimensional stability.

Quality Assurance of our Biaxial Geogrid

StrataGrid™ Biaxial Geogrid, offered by MEGS in collaboration with Strata, is built to perform under pressure. Made from premium materials and manufactured with precision, each roll undergoes rigorous testing for strength, durability, and installation resilience.

Tested at leading labs and compliant with MoRTH and IRC standards, StrataGrid™ ensures reliable, long-term reinforcement for pavements, foundations, and critical infrastructure—delivering performance you can trust, project after project.

Since, StrataWeb® are used for critical designs, it is essential to have a clear understanding of its durability. StrataWeb® undergoes exhaustive testing at internationally reputed laboratories to define all of the above factors.

What are the different stages of testing our Biaxial Geogrid

What are the different stages of testing our Biaxial Geogrid

QC Testing

Pull-Out testing

Construction Damage Testing

UV Protection

Consultation

Smart Solutions. Solid Responsibility.

Smart Solutions. Solid Responsibility.

MEGS Prides itself in its innovative vision that minimizes construction activities, allowing us to provide complete solutions efficiently and on time. By reducing on-site work, we save time and improve productivity. Our engineering solutions are carefully designed to meet international standards, with focusing on lowering carbon footprints and highlighting eco-friendly practices.